Philosophy

My Bicycle Wheel Philosophy

My job is to meet the realistic goals of the rider. By doing so, within the rider's budget, I will produce wheels that are efficient, strong, and light, and will require little or no maintenance. Additionally, by avoiding proprietary parts that are hard for typical bike shops to stock, my wheels are easily serviceable at even a small facility.

My wheels are comfortable, too. Stainless steel spokes make the best wheels. I use J-bend spokes and standard nipples. Stainless steel spokes make wheels that are stiff yet comfortable.

Lacing patterns from radial to four-cross are a matter for me to decide with the rider. Standard crossing patterns are a known quantity, but I recognize the 'cool factor' of radial lacing and have built many such wheels. Radial works well provided that the components are properly chosen.

For me, turning wheels over to a customer is like sending my children out into the world. I like to know how they are doing. I ask customers to give me periodic feedback on how my wheels are meeting their expectations. I value their feedback and trust.

Bicycle wheels are usually taken for granted and appear rather uncomplicated at first. Below the surface though, are myriad mysteries of how they actually work which can be uncovered through deep research and experimentation. I invest a great deal of time toward understanding the physics and engineering of bicycle wheels in great depth.

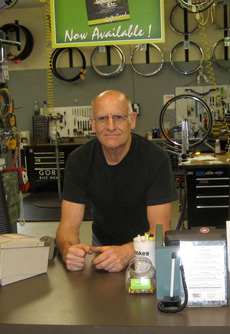

Bill at the service counter of Spokes Etc, where he can be reached at 703-820-2200 or via email: bill@billmouldwheels.com

Bill with Apolo Anton Ohno, an olympic gold medallist in short track speed skating and an avid cyclist, at the U.S. Olympic Training Center in Colorado.

Bill "brings down the hammer" at the 2008 Interbike Expo in Las Vegas, the largest bicycle trade event in North America.